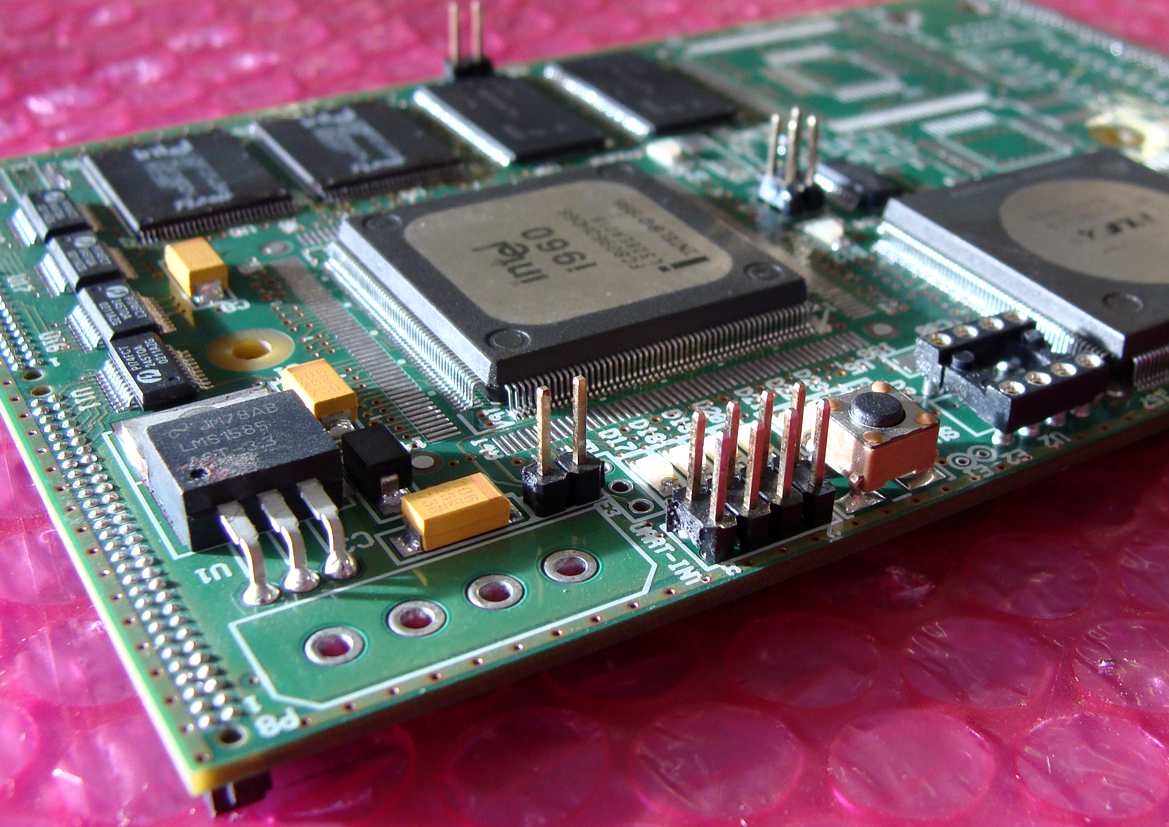

Printed circuits assembly

We assemble the printed circuits using the most recent available technologies.

We are able to produce the electronic boards starting from the gerber file, therefore proceeding with the SMT and PTH assemblies up to the creation of the final product.

We work with the maximum flexibility both from the points of view of the delivery time and of the type of supply.

In order to offer the maximum flexibility we are organized to offer the following methods:

- Full customer care: the customer supplies all the necessary materials needed for the assembly;

- Full Dertel care: Dertel s.r.l. manages the purchase of all the necessary materials needed for the assembly. This is the best solution, that allows you to get the highest quality and a unique supplier that takes care of everything;

- Joint care: Dertel s.r.l. manages partial supply of the material according the agreements with the customer. For example, the customer may decide to supply us only with the printed circuit and a part of the electronic components.

SMT Process

We handle SMT electronic boards with micrometre components (0201), bga, micro bga, fine pitch.

The reflow welding with the vapour phase technology allows very precise thermal profiles and an optimal and controlled welding for any type of electronic boards.

Accurate optical inspections with the aid of microscope guarantee a high quality of the process.

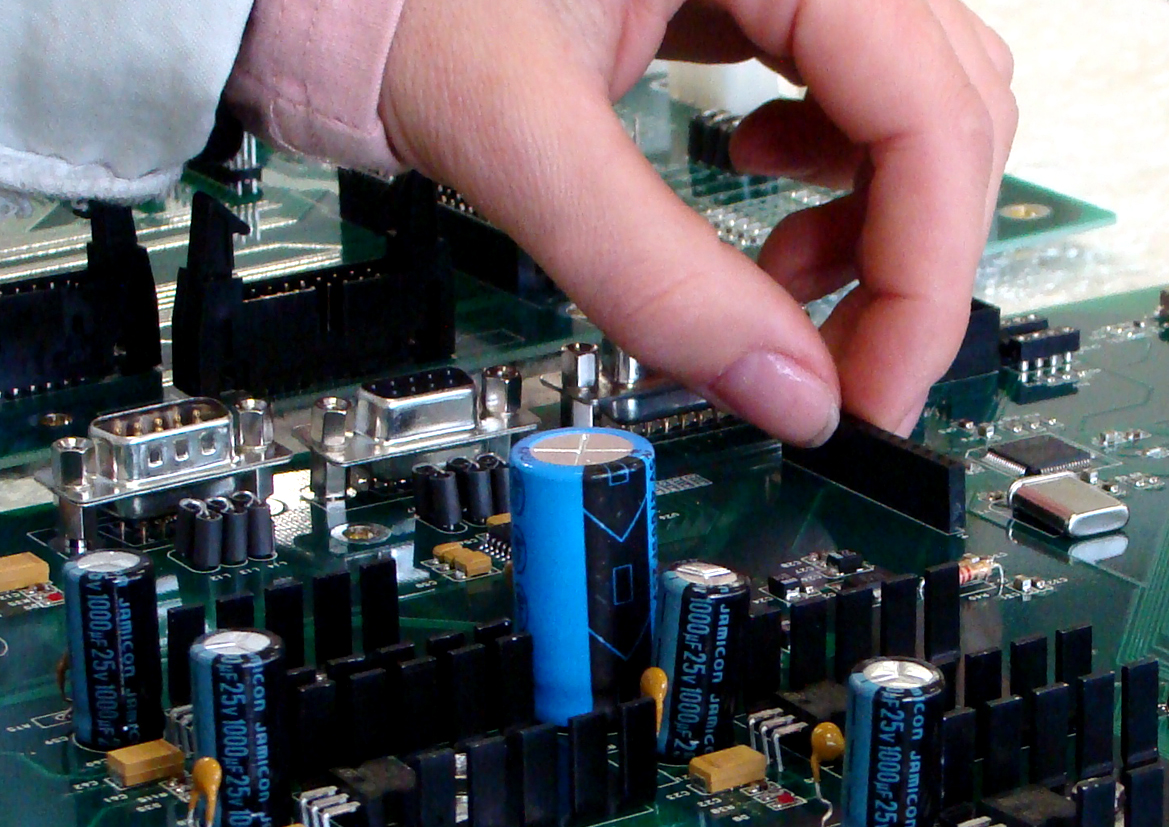

PTH Process (traditional components)

The completion of the PTH components occurs through wave combined welding and possible manual working where it may be necessary or advantageous. There are available two lines, one for the Lead Free and one for SnPb welding (that is dedicated to the exempt sectors).

Via Cavalieri di Vittorio Veneto 8/c

Via Cavalieri di Vittorio Veneto 8/c